Anti - Slip Surface Testing

Relinea is committed to ensuring that we always offer our customers the highest quality, safest, and most durable products. That’s why we carried out the pendulum test to ensure we are delivering the highest slip resistance possible.

What is slip resistance testing?

Slip resistance testing is designed to assess your flooring and calculate its slip risk in line with HSE Slip Resistance guidelines. The “Workplace (Health, Safety and Welfare) Regulations 1992” make it a requirement for local authorities, building owners and facilities managers to make sure that the flooring or surface of the traffic path is not slippery so there is no danger of injury to anybody. By checking the slip resistance of your surfaces, you can ensure that your flooring conforms to workplace regulations as required.

Around 10,000 people get suffer serious injuries from slips and trips each year while at work. In fact, trips and falls account for one-third of all serious injuries, with an average 90% of them resulting in broken bones. The Health and Safety Executive claims reports that slips, trips, and falls cost companies more than £500 million annually. This is in addition to the incalculable cost to the individual from the repercussions, including loss of income, pain, and poor quality of life.

A pendulum test (or PTV testing) is carried out with a specialist regularly-calibrated machine, which simulates the action of a heel swinging as it travels over a surface. The pendulum test is conducted at zero, 45 and 90 degrees in direction and over a number of times to calculate the slip potential/slip resistance rating of your flooring. The pendulum slip test is recognised by the Health and Safety Executive as a reliable and robust test providing accurate analysis on the slip potential of all types of flooring and is the subject of British Standard, BS 7976-2. The pendulum test helps measure slip potential, and fall risk on walking surfaces, including but not limited to floors, ramps, roads, walkways and bridges.

Making sure the flooring materials you choose have passed the pendulum test is a fantastic method to demonstrate to authorities and insurance providers that you have created a safe floor environment. In the event you were to be sued or have legal action taken, it can be used to fend off claims or even better, prevent them from the get-go.

What does the slip testing mean?

The testing is based on a swinging, imitation heel sweeping over a set area of flooring in a controlled manner. The slipperiness of the flooring has a direct and measurable effect on the pendulum test value (PTV) given.

A total of 15 swings is conducted in three directions (0 degrees, 45 degrees, and 90 degrees) and the average provides an overall PTV. Once the average PTV is obtained the number is then assessed against the following scale to indicate the floor’s slip potential.

The required PTV for the GRP flooring for your project should be determined by the intended end use of the floor surface. Higher PTVs may be required if walking on a non-level surface, or an otherwise higher-risk surface such as stairs or somewhere wet such as a car washroom or marina steps.

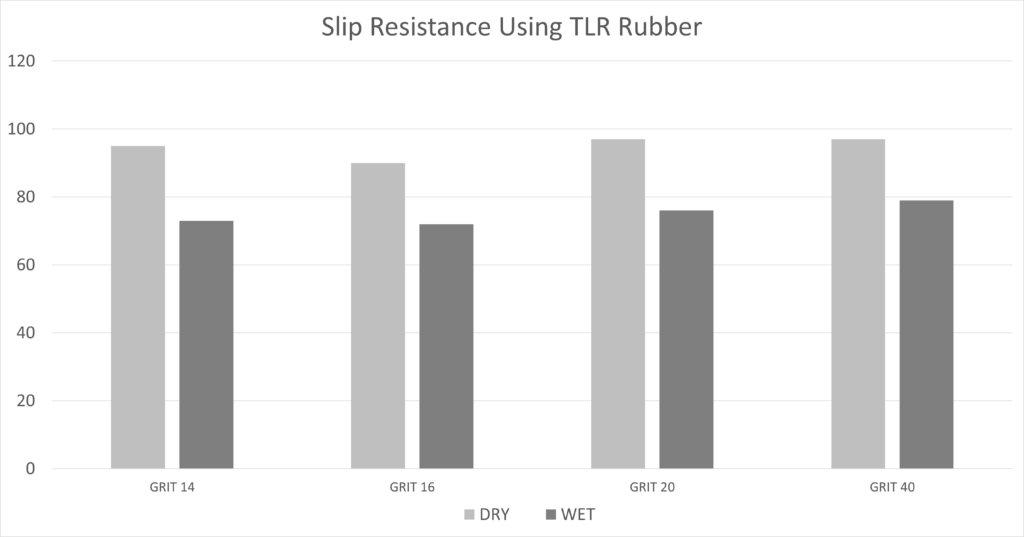

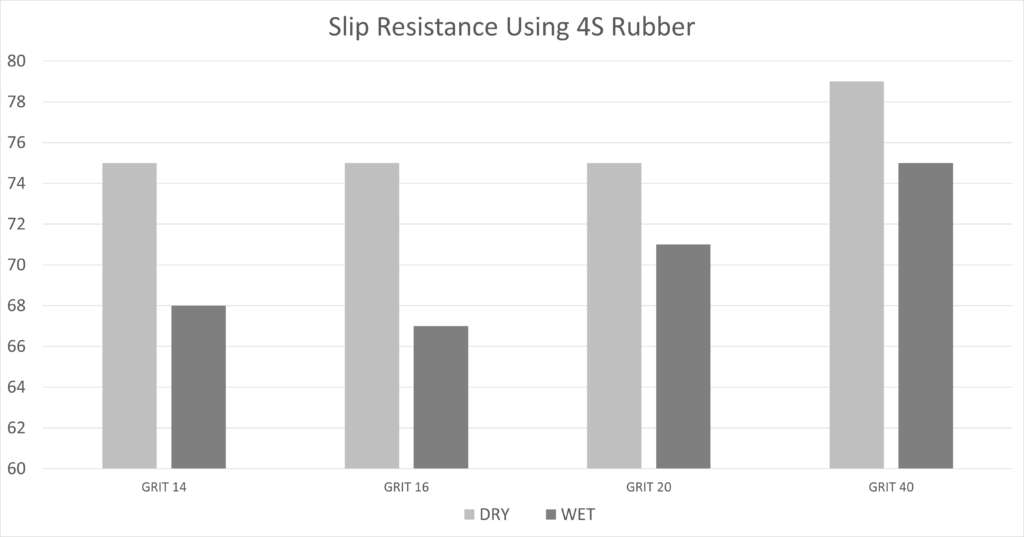

For the test, four specimens of our anti-slip flooring, each bonded with different types of grit – Grit 14, Grit 16, Grit 20, and Grit 40 – were assessed for their dry and wet slip resistance properties using a pendulum test.

To get a fair result we used two different types of rubber. TRL rubber and 4S rubber were used on the pendulum test rig to measure the dry and wet slip resistance properties of the flooring samples.

You can see from the tables above just how well our surfaces performed. Our 40 grit achieved an incredible score of 75 and 79 in the wet, (against the low slip threshold of just 36), making it ideal for almost all flooring conditions. To put it into context, a PTV of 20 indicates a 1 in 2 probability of a slip, and a PVT of 36 indicates a 1 in 1 million probability of a slip.

Did you know…

The “Workplace (Health, Safety and Welfare) Regulations 1992” make it a requirement for local authorities, building owners and facilities managers to make sure that the flooring or surface of the traffic path is not slippery so there is no danger of injury to anybody.

Purpose-driven GRP product design & fabrication

Our GRP innovation challenges construction conventions.

Innovation with purpose.

Our innovative approach to GRP design and fabrication reduces cost and makes installation easier.

Collaborative solutions.

We work with clients to find unique, long-lasting composite solutions.

Use our GRP experience to solve your problems.

15 years GRP experience delivers lighter, lower maintenance alternatives to steel.

We are proud to have built products for