Composite Sandwich Panels

Re-Clad Composite Sandwich Panels offer an attractive yet functional cladding/infill solution for a wide variety of applications. They act as strong as a solid material but weigh significantly less. Sandwich panels are used when a super lightweight assembly is required.

Re-Clad combines Relinea’s Re-plate products that offer a variety of textured finishes with a wide range of core materials that can dictate a number of variables such as the U Value or the Electromagnetic Resistance of the panel.

Our Composite Sandwich Panels are used in Modular Buildings, Railway Stations, Telecom Installations, Curtain Walling and Blast Panels. They are particularly useful where a high-performance cladding is required, with good structural strength, a high level of insulation, and low weight.

Sandwich panels are characterised by their very high load-bearing capacity, excellent robustness, and optimum heat insulation. Relinea Re-Clad composite sandwich panels have numerous advantages that include high tensile strength, resistance to corrosion/chemicals, and non-conductive characteristics. Due to these and many other outstanding qualities, sandwich panels are used for a huge number of purposes, bespoke to each project.

Relinea – Reliable, Resourceful

We are experts with GRP solutions and pride ourselves on offering a bespoke service, industry-leading quality, and excellent value. We happily work with architects, building companies, joiners, and homeowners to provide high-performance solutions to suit your individual needs. Our forward-thinking experienced team delivers efficiency, quality, and the best customer care, providing customers a hassle-free end-to-end solution when purchasing our products.

Give us a call today on 028 9447 0010 or email us at info@relinea.com with your project specification to discuss your requirements and request a free quotation and proposal.

Learn more about Relinea products by downloading one of our brochures

Re-Clad Materials include:

- Plywood

- Polyurethane Foam (PU) – insulating

- Polypropylene Honeycomb

Due to the wide choice of panel and core materials available, products can be made to suit individual customer’s requirements.

Where there is a risk of fire, Class I/O BS 476 Systems come highly recommended, whereas our GRP Phenolic laminates and foams provide the ultimate protection against fire, smoke and toxic emissions. (See Phenolic products technical download)

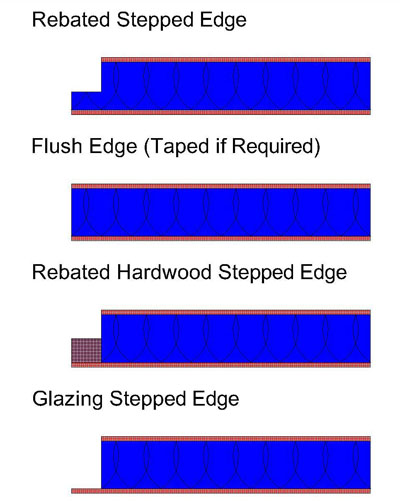

Edge Detail

Our Composite Sandwich Cladding Panels can be supplied with optional edge details specific to customer requirements – for instance rebate edges are normally specified when the panel is to be fitted into a window recess whereas flush edge panels are used for partitioning.

Re-Clad Materials Include

Plywood

Polyurethane Foam (PU) - Insulating

Polypropylene Honeycomb

Composite Cladding

Relinea manufacture and supply a range of high performance, high quality exterior Composite Cladding, Decorative facades and interior surfaces that outperform traditional materials.